MBK Biochar Production: A Technical Overview

MBK International operates one of the most advanced, fully automated carbon removal systems focused on producing high-quality biochar from certified organic biomass. Our approach integrates climate science, robotics, and blockchain transparency to provide traceable and verifiable carbon removal at scale.

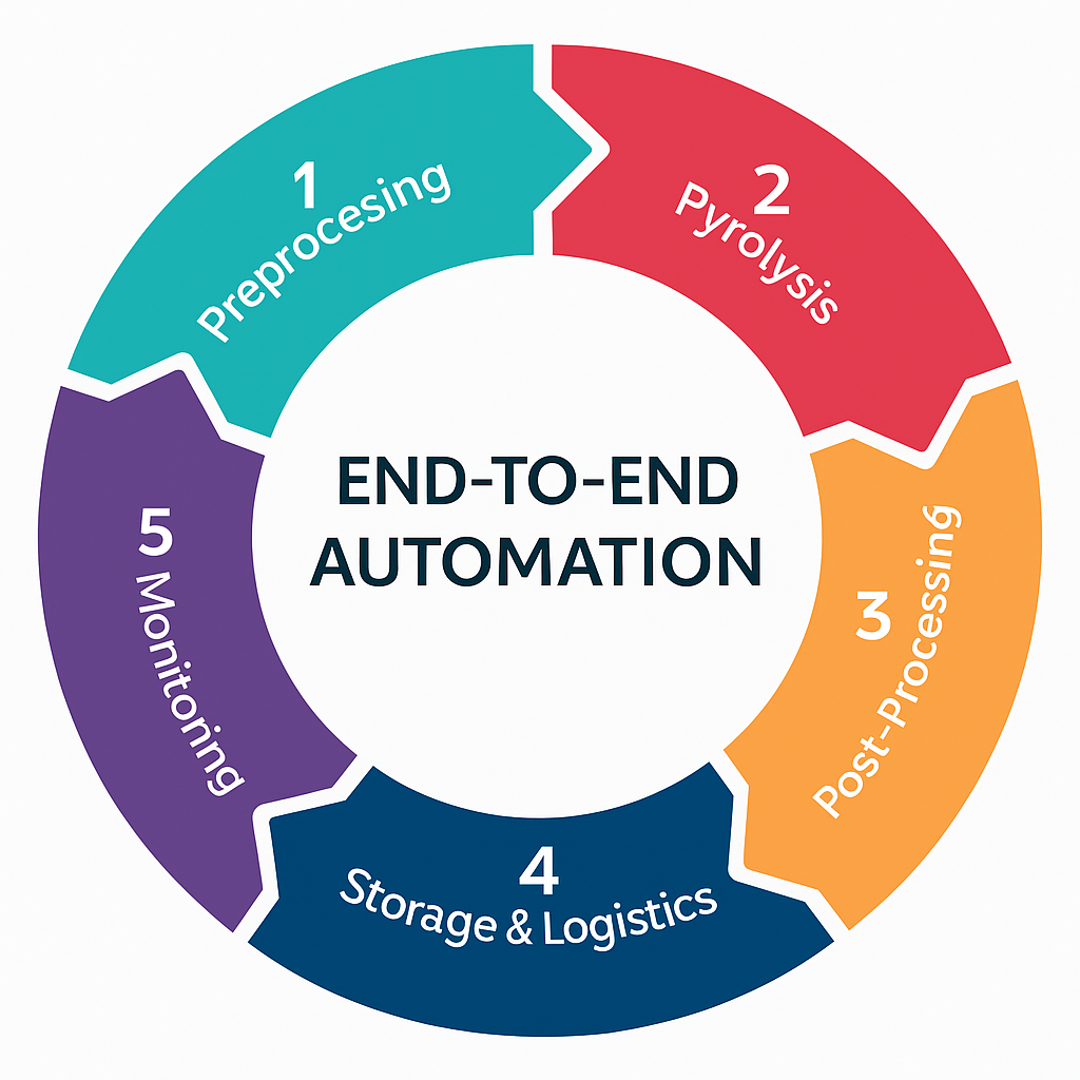

End-to-End System Architecture

Our biochar infrastructure integrates the entire lifecycle of biomass conversion:

- Feedstock Preparation: Agricultural and forestry byproducts are pre-processed, dried, and quality-verified to meet strict environmental and carbon yield standards.

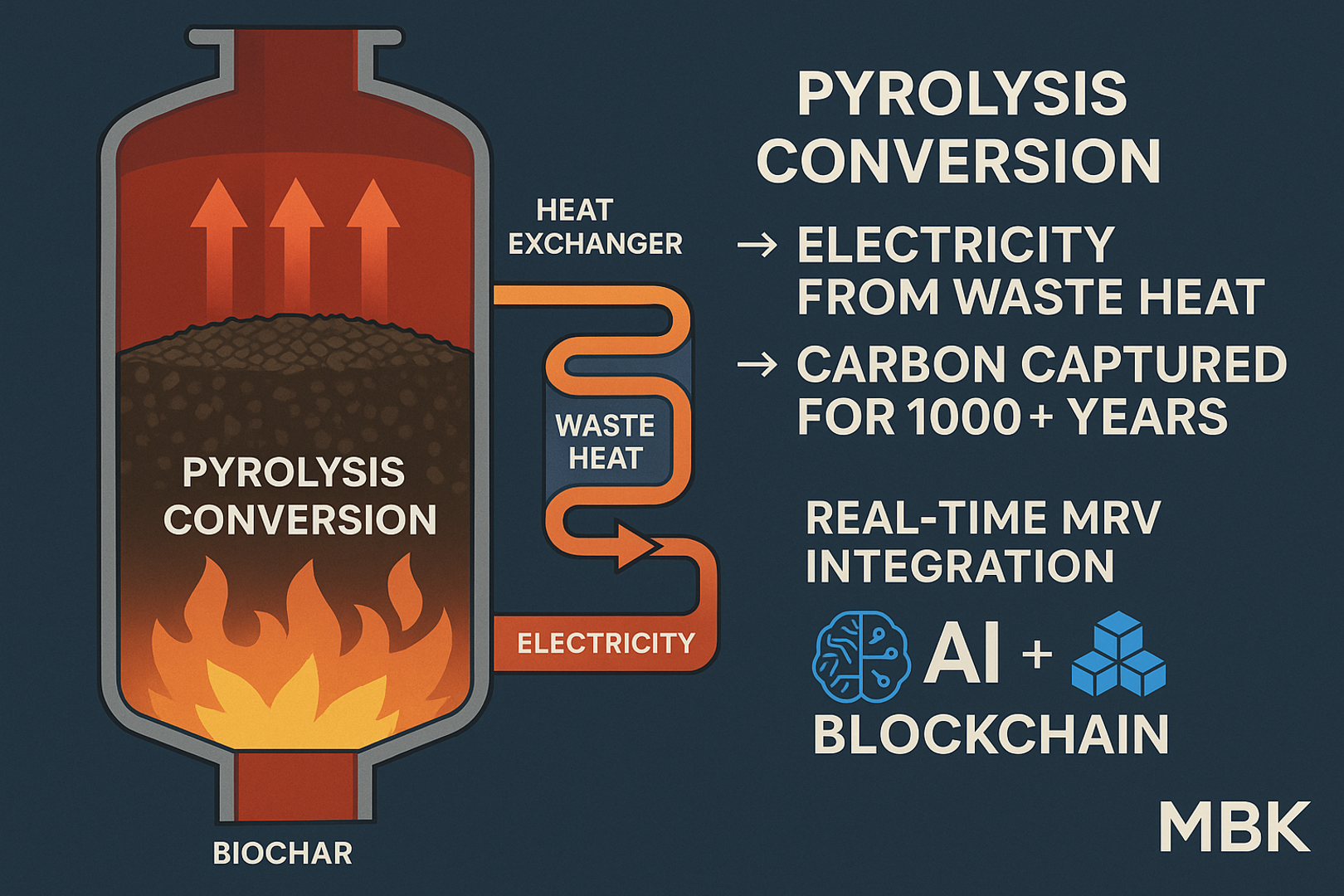

- Automated Pyrolysis: Utilizing continuous-flow, low-oxygen pyrolysis technology, organic materials are thermally converted into stable, carbon-rich biochar.

- Post-Processing & Packaging: The final biochar is cooled, screened, packaged, and QR-tagged for tracking and deployment in agricultural or ESG-certified markets.

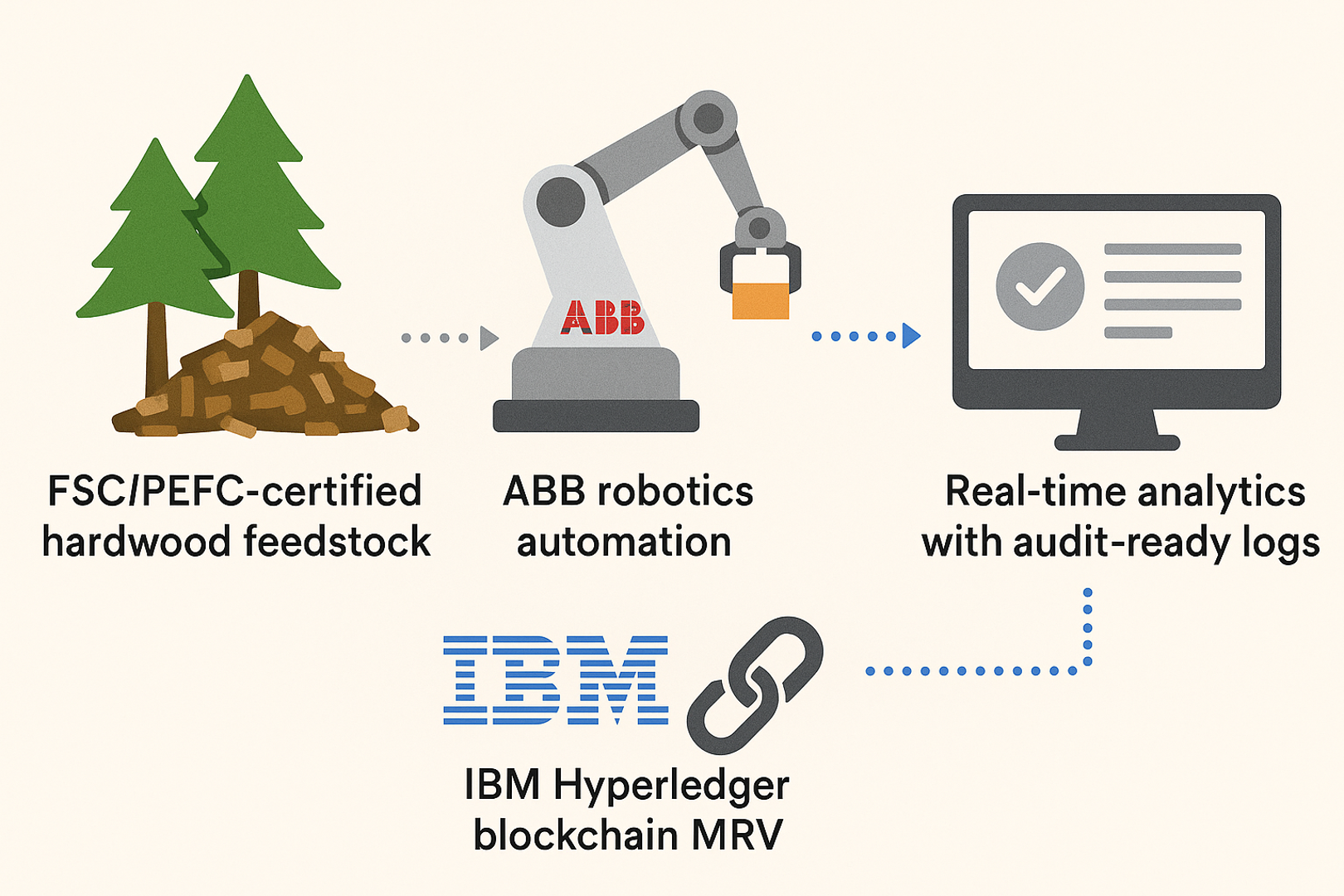

Robotics and AI-Enabled Automation

To ensure consistency, safety, and scalability:

- AI-assisted systems manage sorting, shredding, and feedstock metering.

- Robotic arms perform precise material handling and separate non-compliant items.

- QR-coded batch ID management enables digital traceability from raw materials to the final product.

MRV (Monitoring, Reporting & Verification) Infrastructure

An enterprise-grade MRV platform monitors every production event:

- IBM Hyperledger Blockchain: Records every step of the process—batch ID, energy balance, material flow, as immutable data.

- IoT Sensors & Analytics: Track temperature, gas composition, and carbon content, enabling audit readiness.

- Registry-Ready Export: Supports compliance with leading carbon registries including Verra, Puro.Earth, CAR, and Gold Standard.

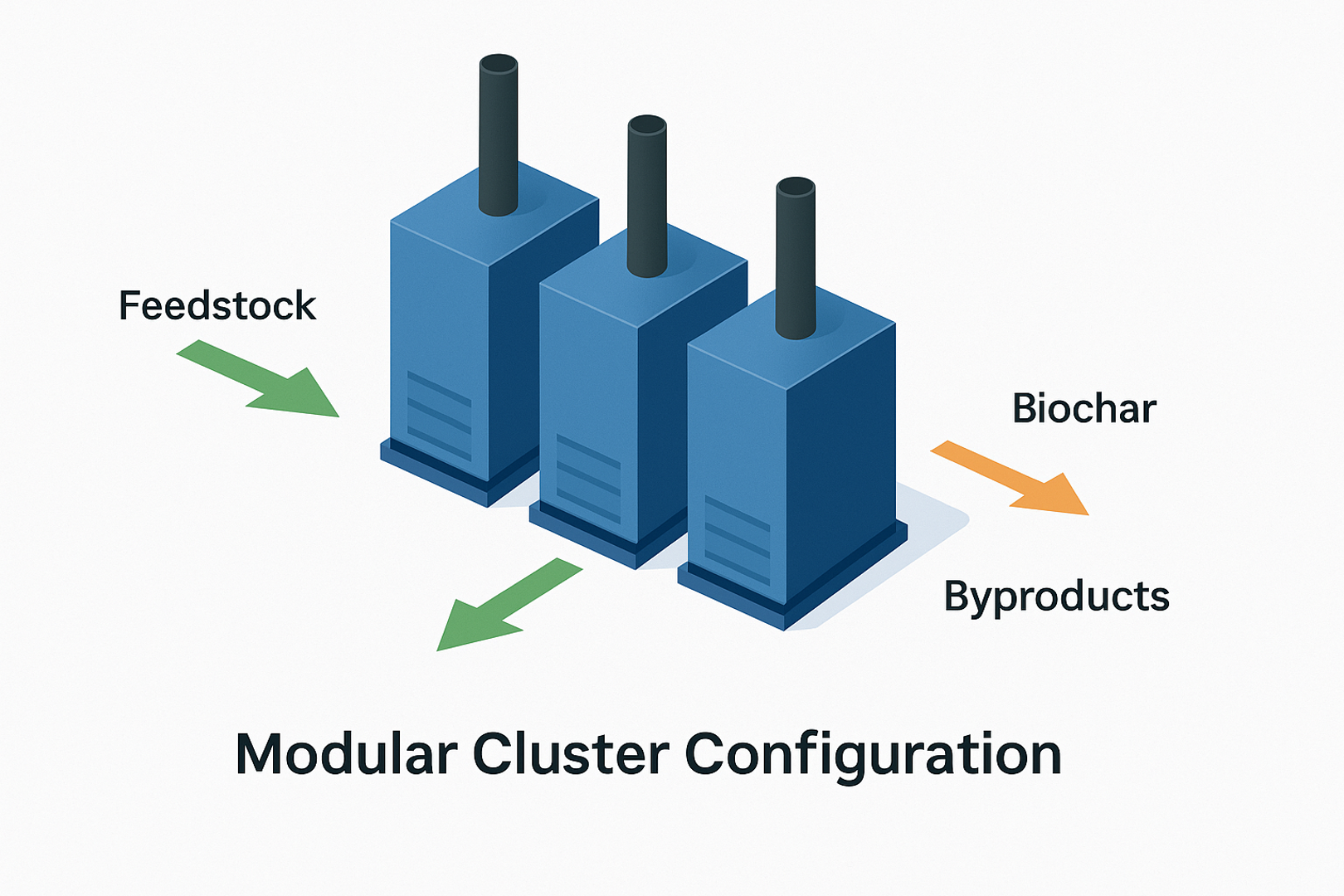

Scalable, Resilient Architecture

- Initial operational capacity of 1 million tons per year.

- Modular upgrades support expansion up to 7 million tons per year.

- Built-in redundancies ensure zero downtime for mission-critical systems.

Global Impact Orientation

MBK’s platform combines robotic precision with climate resilience, facilitating carbon removals that are measurable, permanent, and in line with the highest environmental standards.